| Coating Process | AlCrN, TIN, TICN, DLC, CrN, etc. | |||

| Etch | IET | |||

| Number of Arc Sources | 8PCS | |||

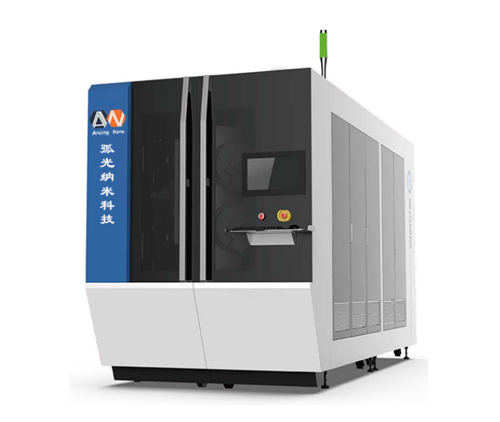

| Equipment Structure | One-piece Construction | |||

| Equipment Specifications | 750*1000(mm) | |||

| Gas | High Purity Industrial Gases | |||

| Chilled Water | Pure Water 3bar、5m³/h | |||

| Average Power | 30KW·h | |||

| Energy Consumption of a Single Furnace | 200kwh | |||