| Coating Material | Coating Name | Coating Colours |

Film Thickness (μm) |

Durometer (HV) |

Maximum working temperature(°C) |

Coefficient of friction (steel dry grinding) |

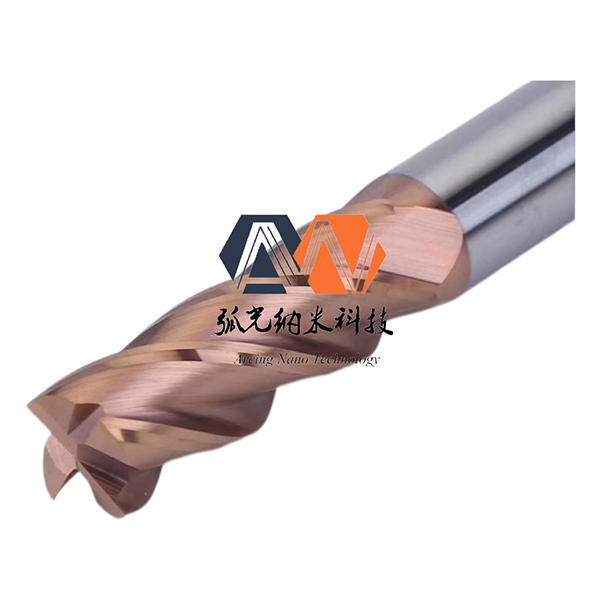

| TiSiN | Titanium-silicon | Bronze | 1~4 | 2000 | 800 | 0.3 |

| Main Features | High hardness, excellent resistance to high temperature oxidation, thermal stability, high wear resistance | |||||

| Applications | Suitable for hard cutting tools, drilling aspects, stainless steel products | |||||

|

|

||||||