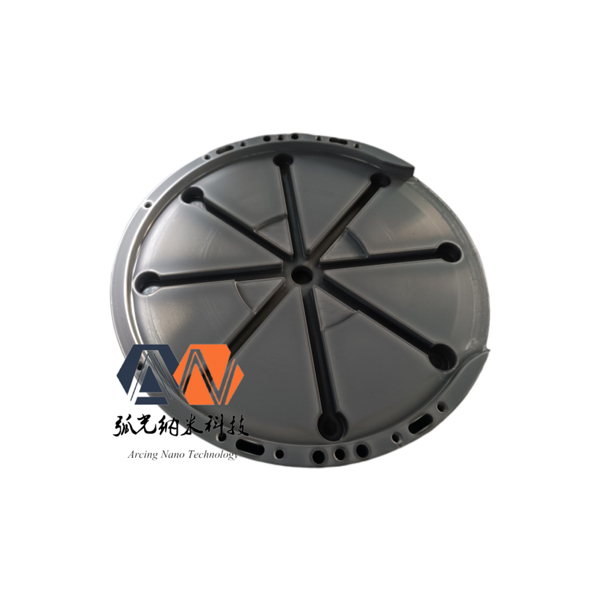

Product Details

(1) Improve surface hardness and wear resistance: Ion nitriding

significantly improves the surface hardness and wear resistance of

moulds by forming a nitriding layer on the surface of the moulds, thus

prolonging the service life of the moulds;

(2) Enhance fatigue

strength and corrosion resistance: the nitriding layer not only improves

the hardness of the mould, but also enhances its fatigue strength and

corrosion resistance, which further protects the mould from damage;

(3) Control the organisational structure of nitriding layer: by

adjusting the ratio of nitrogen, hydrogen and other gases, the phase

composition of the compound layer can be freely adjusted to obtain the

expected mechanical properties;

(4) Applicable to a variety of

materials: ion nitriding is applicable to a variety of materials,

including steel and other metals, improving its applicability and

flexibility;

(5) Small deformation: due to the treatment at low

temperature, the deformation of the treated workpiece is extremely

small, and there is no need for further processing after treatment,

which is extremely suitable for the treatment of finished products;

(6) Easy to achieve local nitriding and uniform nitriding: ion nitriding

is easy to achieve local nitriding and uniform nitriding, and the area

and degree of nitriding can be precisely controlled according to the

needs;

(7) Light pollution to the environment: Ion nitriding is

carried out in a vacuum, which does not produce harmful emissions and

causes less pollution to the environment, while the labour conditions

are also improved.