Product Details

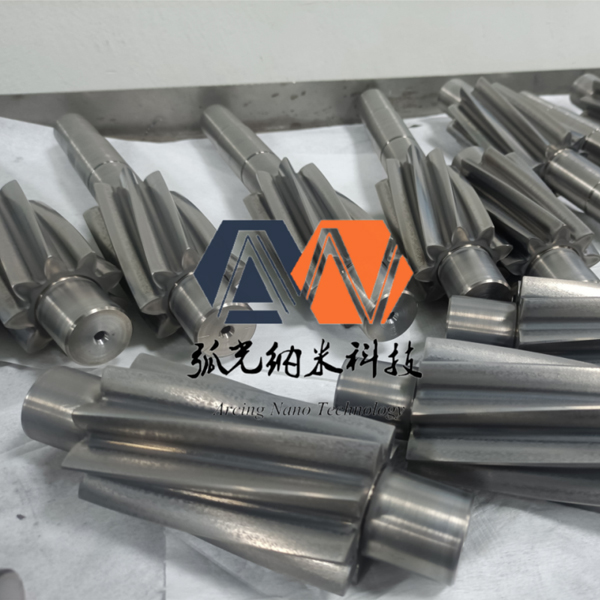

Ion nitriding technology has a significant impact on the performance enhancement of parts such as bearings and turbine worm gears. Ion nitriding, also known as glow nitriding, is a chemical heat treatment process using the principle of glow discharge. In this process, the metal workpiece is placed as the cathode in a negative pressure container with a nitrogen-containing medium, and after the electricity is energised, the nitrogen and hydrogen atoms in the medium are ionised, forming a plasma zone between the cathode and the anode. This treatment can form a layer of high hardness nitride layer on the surface of the workpiece, thus improving the wear resistance, corrosion resistance and fatigue strength of the parts.

Ion nitriding technology is especially important for parts that require high wear resistance and durability, such as bearings and worm gears. Through ion nitriding, the surface of these parts can be strengthened, thus improving their service life and work efficiency. In addition, ion nitriding has the advantages of fast nitriding speed, small deformation and easy protection, which makes it particularly popular in industrial applications. Ion nitriding technology is one of the indispensable technologies in the industrial field by improving the surface properties of bearings, worm gears and other parts, which prolongs their service life and improves their working efficiency.